CORESIC® SP

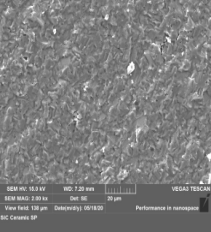

CORESIC® SP silicon carbide is a kind of self bonded fine crystalline alpha type silicon carbide. Sanzer uses spray granulation of ultra-fine silicon carbide micro-powder, which is then formed by Sanzer special methods of isostatic pressing and dry pressing. Its density is 98% higher than the theoretical density.

Superior Properties

High strength, high density, hardness close to diamond, and wear resistance;

High strength, high density, hardness close to diamond, and wear resistance;- Excellent chemical stability, resistant to various acids, alkalis and organic solvents;

- High thermal conductivity, low coefficient of thermal expansion, heat shock resistance, and the lowest thermal deformation;

- High temperature resistance above 1600 degrees Celsius, with excellent antioxidant performance;

- The resistivity is between 106-108 Ω, non magnetic, and meets the requirements of ESD resistance specifications;

- High specific stiffness and excellent thermal uniformity, resistant to bending and deformation after long-term use;

- Comprehensive chemical corrosion resistance

- Resistant to plasma, particularly suitable for etching equipment;

- Low density and light weight.

Features and Applications

CORESIC® SP silicon carbide ceramic material has excellent mechanical properties, excellent high-temperature stability, as well as good specific stiffness and optical processing performance, making it particularly suitable for precision ceramic structural components such as optoelectronic lighting, semiconductors, electronic glass, aerospace, and national defense and safety.

Material Performance Table

Key words:

Recommend News

Silicon Carbide Optical Mirrors for Precision Optics in Aerospace and Defense

Silicon carbide (SiC) optical mirrors are emerging as a critical component in high-precision optical systems, particularly in the aerospace and defense sectors. Manufactured through processes like direct isostatic pressing and pressureless sintering, these mirrors can be tailored to various structural shapes to meet specific design requirements. With their exceptional properties, SiC optical mirrors are finding applications in laser mirrors, infrared mirrors, and array mirrors, contributing to advancements in optical technologies.

Silicon Carbide RTA Carrier Plates A Robust Solution for High-Temperature Applications

Silicon carbide RTA carrier plates are essential components in the manufacturing of LED chips, where they play a critical role in the rapid thermal annealing (RTA) process. This specialized application demands materials that can withstand the extreme temperatures and rapid heating/cooling cycles inherent to RTA. Silicon carbide (SSiC) plates excel in this realm due to their unparalleled strength and durability.

The Superior Properties and Applications of Silicon Carbide Heat Exchange Plates

In the realm of industrial heat management, Silicon carbide heat exchange plates stand out for their exceptional properties. Crafted through isostatic pressing and high-temperature sintering, these plates can be engineered to meet precise design specifications, accommodating various structural shapes. Their versatility is such that they can accommodate minimal channel sizes of just 1mm, making them adaptable for intricate heat exchange requirements.

Silicon Carbide Round Crucibles A High-Performance Material for High-Temperature Applications

Silicon carbide round crucibles are a critical component in various high-temperature industrial processes, where their exceptional properties make them indispensable. Manufactured using isostatic pressing techniques and high-temperature sintering, these crucibles are available in round shapes, as well as square configurations, with a variety of bottom types such as flat, semi-flat, and spherical. Furthermore, they can be customized with flanges, drilled holes, and other processing specifications to meet specific application requirements.

Consultation hotline:

Address:No.99 East Changxing Road, Nantong Economic and Technological Development Zone, Jiangsu

Email:market@sanzer.com

Fax:86 21 5954 9392

Website:www.sanzer.com

WeChat Public Number

Enterprise WeChat

WeChat Public Number

Copyright©2022 Jiangsu Sanzer New Materials Technology Co., Ltd. 沪ICP备XXXXXXXX号 SEO Power by:www.300.cn