Popular Product Keywords:

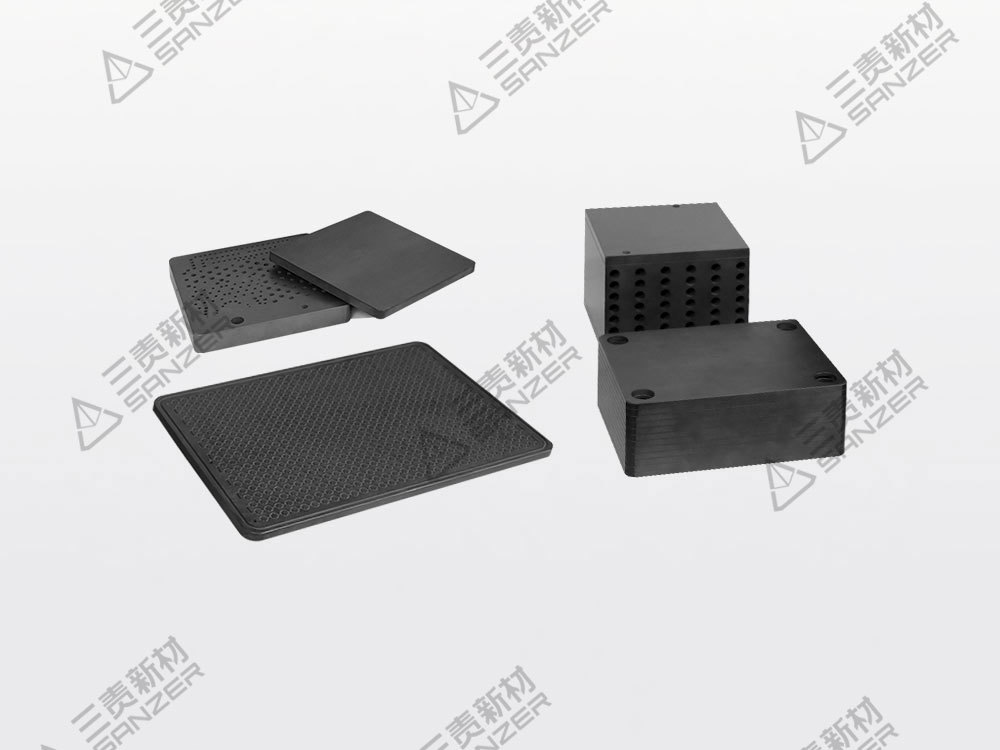

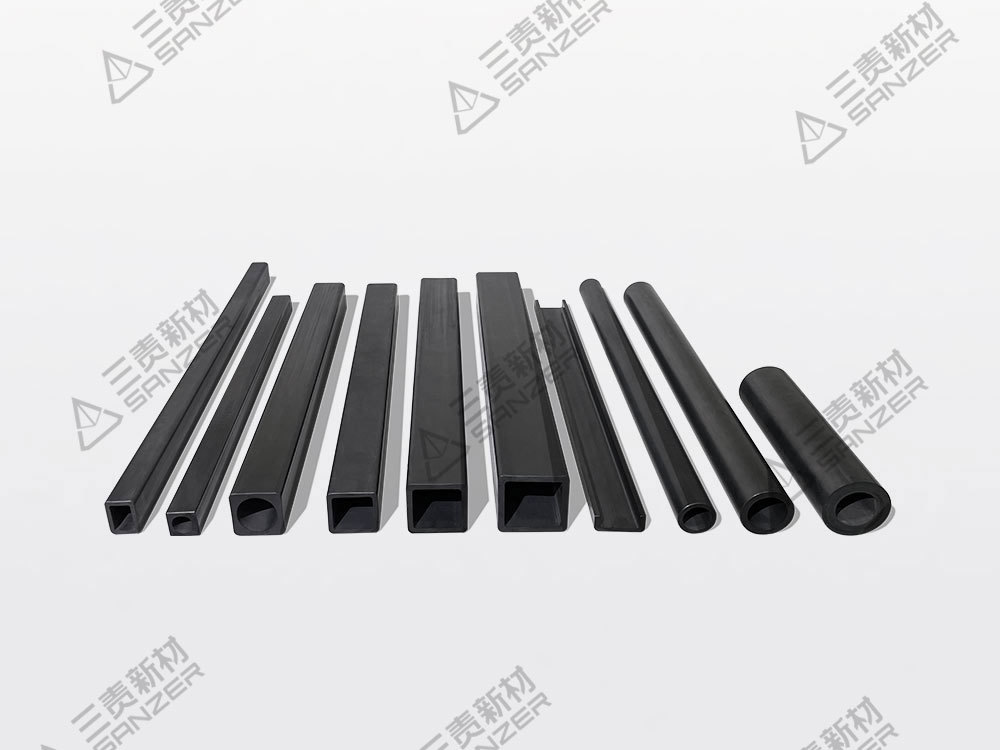

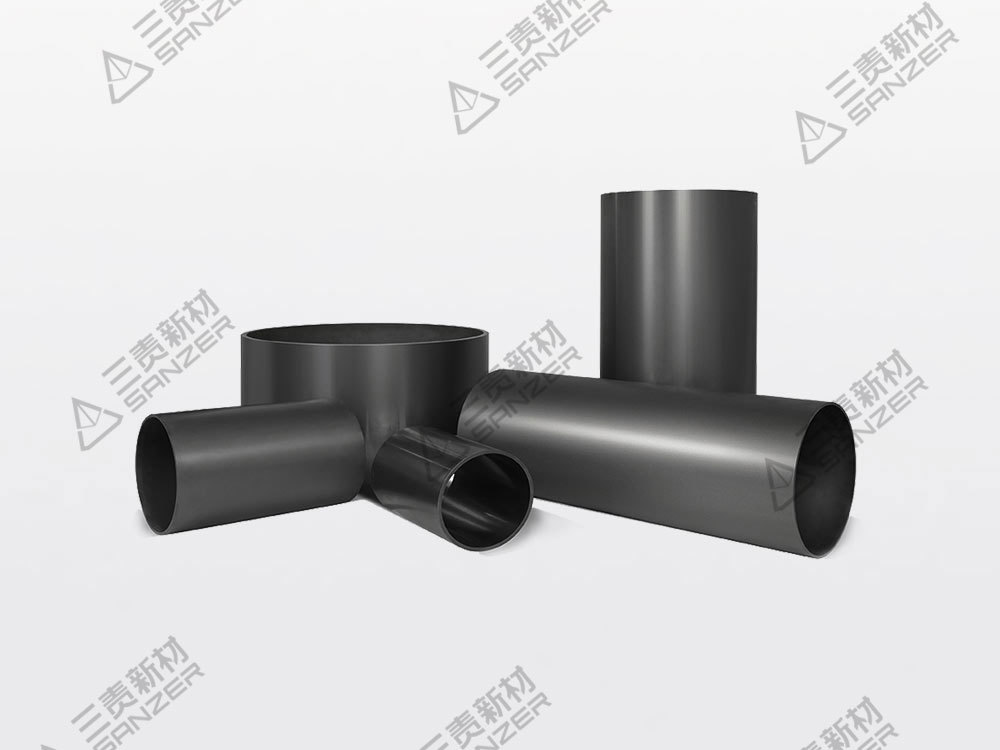

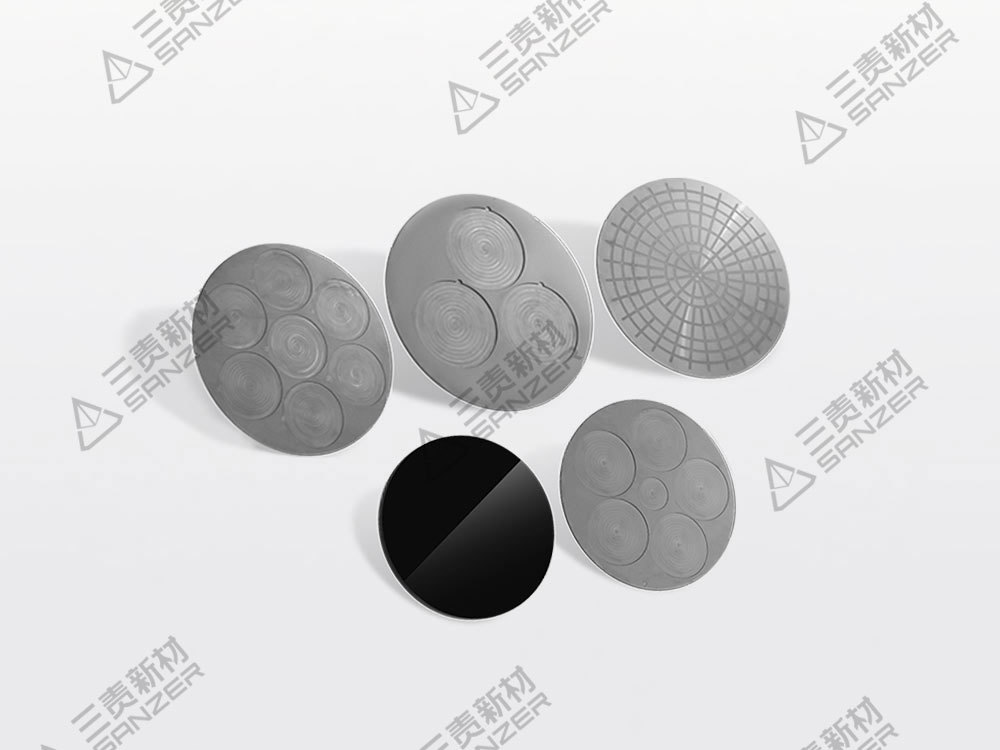

Silicon Carbide Cantilever Paddle,Boat Bracket,Wafer Boat,Square Beam,Roller

Materials

The use of ultrafine silicon carbide micropowder (particle size usually in 0.5-1.0μm) as raw materials, adding certain sintering additives, such as solid-phase system is generally used in B4C-C, the liquid-phase system is generally used in Al2O3-Y2O3, usually need to add binder, dispersing agent, and other organic solvents, the formation of granulated powder through spray drying process, the use of a variety of molding processes, high temperature sintering in vacuum or under argon gas protection ( Temperature is usually 2100-2200 ℃), the sintered density is usually greater than 98% of the theoretical density, the density is generally 3.10-3.18g/cm3, grain size is generally not more than 20μm.

View DetailsUsing different particle size silicon carbide powder as raw material, introducing inorganic or organic carbon source, combined with forming methods such as slip casting, gel casting, isostatic pressing, extrusion, to produce SIC + C substrate, and degreasing, high temperature reactive silicone seepage sintering under vacuum atmosphere (temperature is usually in the range of 1600-1700 °C), to get the combination of primary and secondary silicon carbide silicon carbide material, the material usually contains a certain percentage of free silicon, usually within 15%, with a density of 3.03 or more. In addition, the purity of the material can be controlled according to the actual application conditions of the material to adapt to different application environments.

View DetailsProducts

Products

Products

Application

News

Sanzer New Materials at CIBF in Shenzhen, 16-18 May 2023

19

2023-05

Sanzer New Materials at CIBF in Shenzhen, 16-18 May 2023

Sanzer New Materials at Ceramics Expo in Michigan, 1-3 May 2023

12

2023-05

Sanzer New Materials at Ceramics Expo in Michigan, 1-3 May 2023

Sanzer New Materials at the 2nd Advanced Ceramics Summit Forum

24

2023-04

Sanzer New Materials at the 2nd Advanced Ceramics Summit Forum

Sanzer New Materials at the 7th Power Lithium Battery Cathode Material Summit, 12 July, 2022

14

2022-07

Sanzer New Materials at the 7th Power Lithium Battery Cathode Material Summit, 12 July, 2022

03

2021-08

Consultation hotline:

Address:No.99 East Changxing Road, Nantong Economic and Technological Development Zone, Jiangsu

Email:market@sanzer.com

Fax:86 21 5954 9392

Website:www.sanzer.com

WeChat Public Number

Enterprise WeChat

WeChat Public Number

Copyright©2022 Jiangsu Sanzer New Materials Technology Co., Ltd. 沪ICP备XXXXXXXX号 SEO Power by:www.300.cn