SSiC

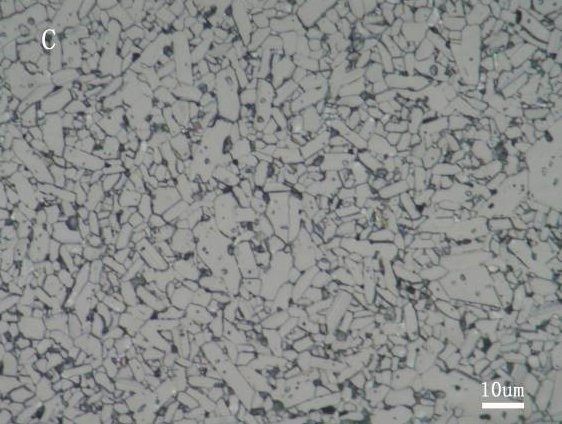

The use of ultrafine silicon carbide micropowder (particle size usually in 0.5-1.0μm) as raw materials, adding certain sintering additives, such as solid-phase system is generally used in B4C-C, the liquid-phase system is generally used in Al2O3-Y2O3, usually need to add binder, dispersing agent, and other organic solvents, the formation of granulated powder through spray drying process, the use of a variety of molding processes, high temperature sintering in vacuum or under argon gas protection ( Temperature is usually 2100-2200 ℃), the sintered density is usually greater than 98% of the theoretical density, the density is generally 3.10-3.18g/cm3, grain size is generally not more than 20μm.

Key Advantages

- Super hardness, excellent wear resistance (typically Vickers hardness over 2000 GPa)

- Very high bending strength (usually three-point bending strength greater than 350 MPa)

- High temperature resistance (typical use temperature over 1500°C)

- High thermal conductivity (room temperature thermal conductivity typically greater than 120 W/m/K) and low coefficient of thermal expansion (room temperature CTE typically less than 2.5 ppm/°C)

- Comprehensive chemical and ion etching resistance (non-pressurized solid phase systems are resistant to strong or complex acids, including hydrofluoric acid, for long periods of time)

- Enables the manufacture of large-sized and complex structural components

Key words:

Recommend News

What’s special about Silicon Carbide Heat Exchange Tubes?

Silicon carbide heat exchange tubes are fabricated through extrusion molding and high-temperature sintering. Sanze uses a laser aligning instrument to monitor the outer diameter of the tubes, ensuring that the qualified products have uniform tube walls, smooth surfaces, and excellent roundness and straightness. According to the special requirements of customers, local polishing can be conducted on the outer diameters at both ends of the tubes.

Why Choose Silicon Carbide Header?

Silicon carbide header is a remarkable product that is fabricated through isostatic pressing and high-temperature sintering. It can be assembled with silicon carbide blocks to form a silicon carbide block heat exchanger. The inlet and outlet sizes and sealing methods can be designed according to specific design requirements.

What are the main features of Silicon carbide heat exchange block?

The Silicon Carbide Heat Exchange Block is an innovative solution crafted using advanced manufacturing techniques such as direct isostatic pressing and pressureless sintering. Its design enables efficient heat transfer between two mediums through the walls of longitudinal and transverse channels, with customizable pore sizes and wall thicknesses. The minimum pore diameter can be as small as 6mm, while the thinnest wall can reach 2.5mm, offering unmatched precision and flexibility.

What is Silicon carbide tubesheet?

Silicon carbide tubesheet is a remarkable material that plays a crucial role in various industries. These tubesheets are fabricated through isostatic pressing and high-temperature sintering. They can be assembled with silicon carbide heat exchange tubes to form silicon carbide shell and tube heat exchangers, which are primarily utilized in high-temperature, high-pressure, and highly corrosive working conditions. The sealing method can be designed according to the design requirements, and threads can also be machined.

Consultation hotline:

Address:No.99 East Changxing Road, Nantong Economic and Technological Development Zone, Jiangsu

Email:market@sanzer.com

Fax:86 21 5954 9392

Website:www.sanzer.com

WeChat Public Number

Enterprise WeChat

WeChat Public Number

Copyright©2022 Jiangsu Sanzer New Materials Technology Co., Ltd. 沪ICP备XXXXXXXX号 SEO Power by:www.300.cn