12-24

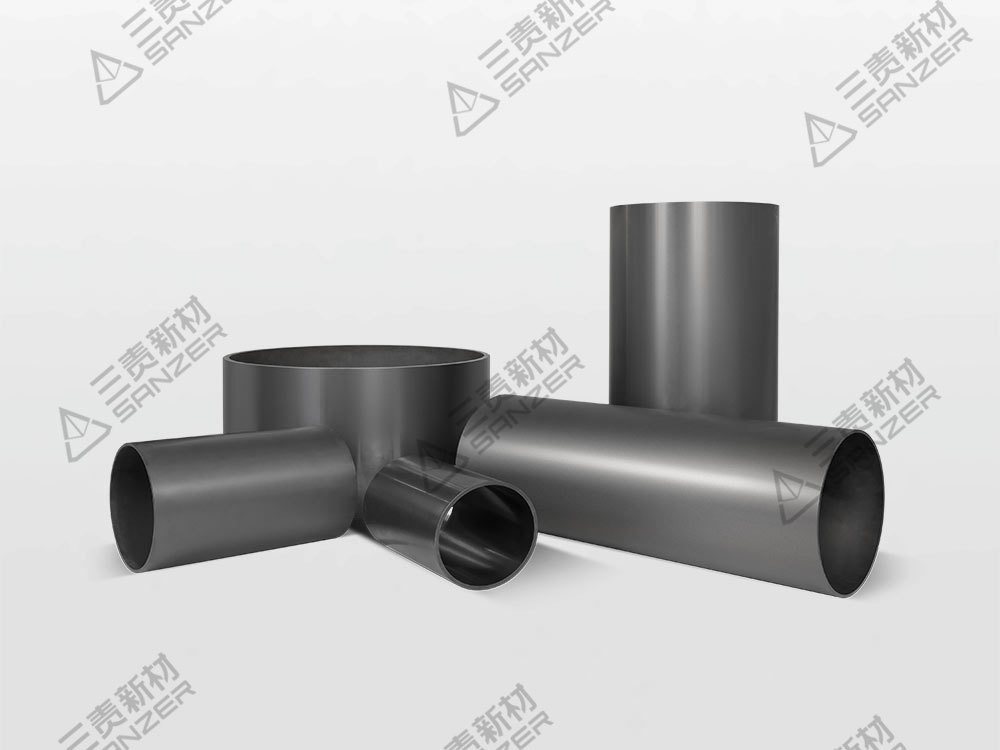

What’s special about Silicon Carbide Heat Exchange Tubes?

12-17

Why Choose Silicon Carbide Header?

12-10

What are the main features of Silicon carbide heat exchange block?

12-03

What is Silicon carbide tubesheet?

11-27

Silicon Carbide Bundleblock High-Performance Heat Exchangers

11-20

Silicon Carbide Grinding Liner Tube High-Demand Applications

11-13

Silicon Carbide Sulfuric Acid Atomizing Nozzle Various Applications

11-06

Silicon carbide slurry atomizing disc/nozzle

Consultation hotline:

Address:No.99 East Changxing Road, Nantong Economic and Technological Development Zone, Jiangsu

Email:market@sanzer.com

Fax:86 21 5954 9392

Website:www.sanzer.com

WeChat Public Number

Enterprise WeChat

WeChat Public Number

Copyright©2022 Jiangsu Sanzer New Materials Technology Co., Ltd. 沪ICP备XXXXXXXX号 SEO Power by:www.300.cn